Millwright Reverse Engineering and build services

Prime Field Service Millwright Reverse Engineering and Build Services

Prime Field Service Millwrights and engineers provide world class reverse engineering services

Prime Field Service staff is available to assist you in even the most challenging reverse engineering, rapid prototyping, or “top down” new design projects. Using the latest in CAD/CAM/CAE/FEA-FEM methods, software, and tools, you will get the fastest and most cost effective solution to your Manufacturing needs. We are world class at going from measurement, through modeling, to manufacture of components. We have the state the art measuring tools, with experienced technicians, together with state of art data manipulation, skilled manufacturing technicians, that comprehend the functional aspects with the state of art software, and a complete shop with both fabrication and machining capabilities to manufacture your components. We use laser trackers, laser scanners, faro arms for measuring precision three dimensional profiles.

Prime Field Service measurement millwrights and engineers solve defense issue with reverse engineering and build service.

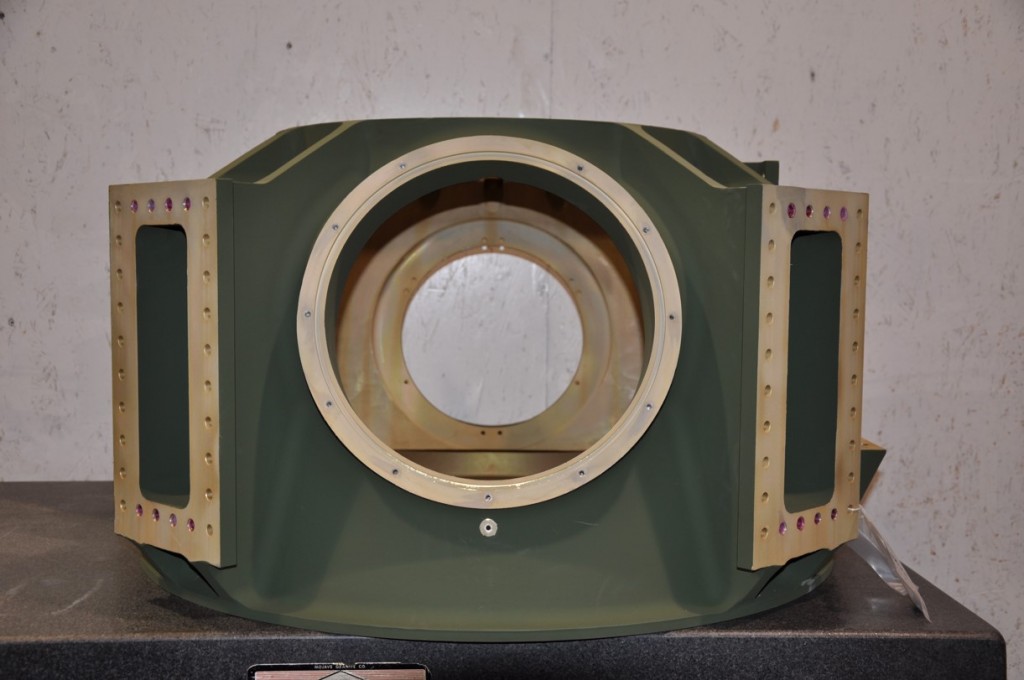

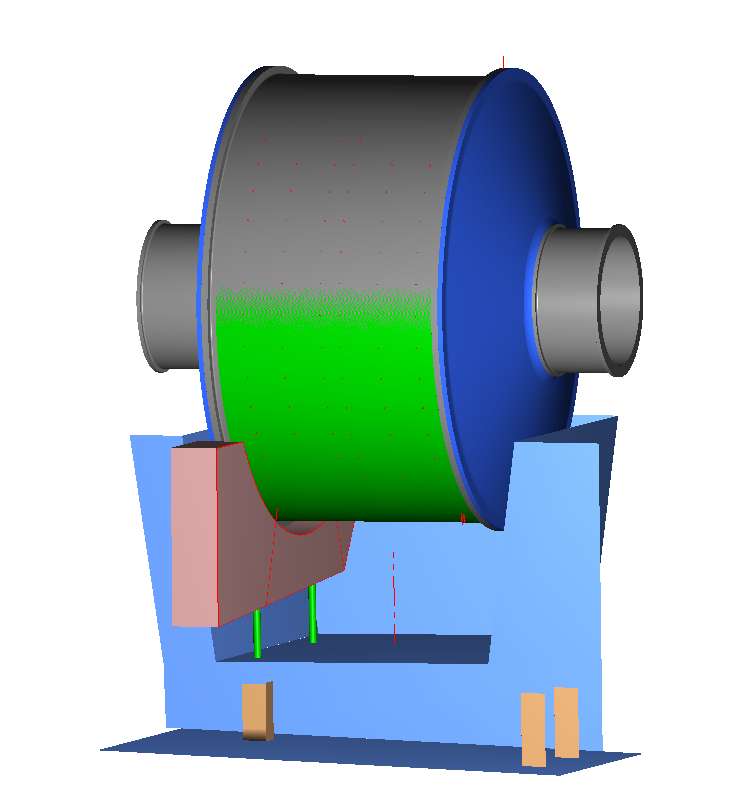

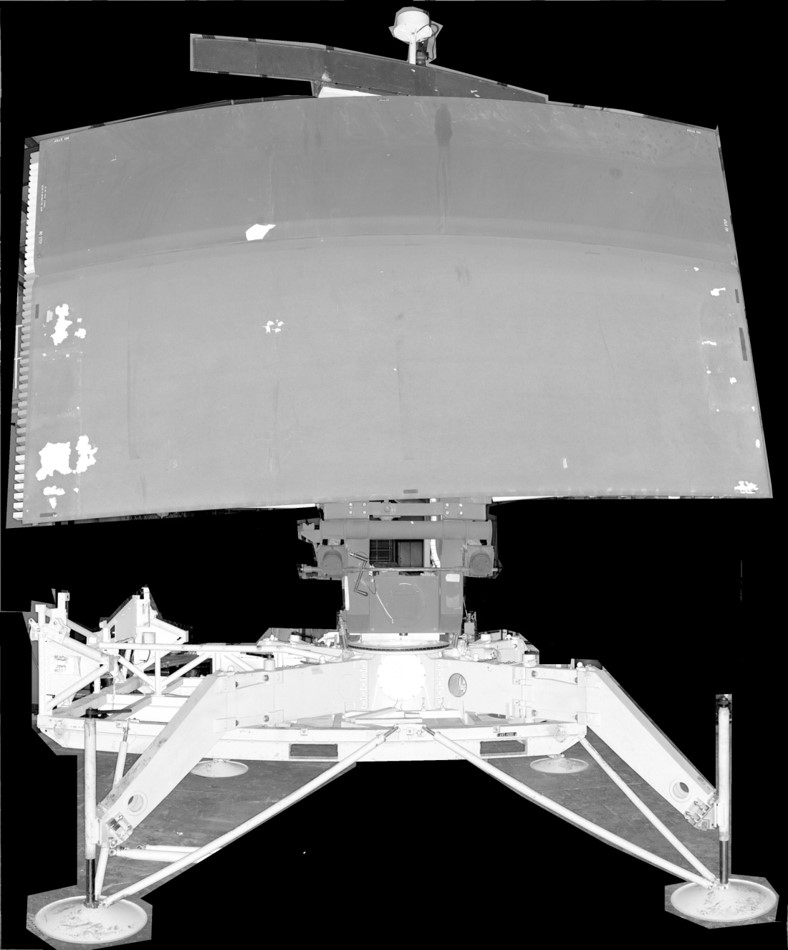

After the events of 911 it was determined that there was an immediate need for radar systems to detect low flying aircraft around American cities. There were existing radars but they had issues with gear boxes and that needed upgraded and replaced. Prime was hired to measure radars and contracted to build a new gear housing box.

Prime Field Service measurement crews created a plan, scanned the radar system, acquired accurate measurements of the entire system for purpose of building new gear box housing from the reversed engineering data.

Prime Field Service millwright measurement crew laser scanner technicians scanned high density data cloud used to three dimensional model radar system.

Prime Field Service in conjunction with Prime Machine create three dimensional model and machine a complete housing from solid block of aluminum for a replicated gear box housing in weeks.

Our technicians are experienced in taking concepts to reality, their broad experience base aides in avoiding manufacturing mistakes that cost tremendously in production or operation of a product or process. This experience is also invaluable when it comes to Reverse 3 D modeling, Re-design, or Retro-fit of a project.

So whether your looking to take an existing design to reality, improve an existing product or process, Reverse manufacture a part, or just have a great idea that you’d like to see come to fruition, Prime Machine is the place you want to be. We are able to replicate almost any mechanical part similar to the Star Track Replicator.

Prime Field Service project to drill oversized liner holes during shutdown period on ball mill for better support of mill liners.

Reverse engineering of large ball mill to get accurate measurements to design a drill jib for the purpose of drilling new liner holes to improve liner support.

Prime Field Crew using the designed drill jig to drill new liner holes in ball mill. Larger bolts were needed to hold the mill liners in place.

This heavy industrial project is world class. Ball mill needed to have liner bolt holes repaired. Prime measured mill with laser scanner, manufactured a drill system to fit mill and drill holes, then scheduled a down to drill holes and make repairs in two days saving mine a substantial amount of down time and money.